Get A Quote

How packaging costs can be reduced?

Packaging does much more than just protect products; it's a powerful tool for making a lasting impression on customers. It has the potential to convert one-time buyers into loyal patrons. Research has shown that effective packaging can significantly boost product sales.

The use of plastics in packaging is noteworthy, with global usage reaching approximately 460 million metric tons in recent years. Packaging alone constitutes 31% of this total, highlighting its extensive use and impact.

The packaging market is vast and growing. The global industrial packaging sector is valued at $62.32 billion and is anticipated to climb to $75.54 billion by 2025. Similarly, the food packaging market is projected to expand from $338.34 billion in 2021 to $478.18 billion in 2028.

However, there's a shift towards environmental sustainability. The market for biodegradable packaging materials is expected to exceed $169 billion by 2032. This change reflects the rising trend of conscious consumerism, where packaging plays a pivotal role in marketing strategies.

Factors Affecting the Packaging Cost

1.Material Costs

Common packaging materials include cardboard, plastic, and paper, each varying in cost. The material you choose significantly influences the overall packaging expense. A report from Packaging News highlighted that high material costs often stem from increased prices of raw materials and production expenses, which inevitably affect what you pay for these materials.

For eCommerce businesses, material selection is influenced by factors like the product's type, weight, shape, size, required protection level, and industry regulations. Since materials have different price points, finding a balance between cost, sustainability, and functionality is key.

To manage costs, consider options like sourcing from suppliers offering competitive prices or making bulk purchases to reduce per-unit costs. Remember to account for additional expenses such as shipping and taxes.

2.Size and Weight Considerations

Larger and heavier packages demand more materials, which can increase packaging costs. They are also less economical with suppliers charging weight-based shipping fees.

Over-sized packaging often requires extra fillers, adding to the cost. If your business involves storage, larger packages need more space and potentially incur higher handling costs, like manual sorting.

To protect profit margins, aim to minimize packaging size. 'Right-sizing' not only cuts costs but also enhances eco-friendliness.Regarding material weight, while plastic is lightweight, cardboard offers a more sustainable option.

The role of automation in packaging

Investing in advanced packaging equipment and technology can greatly boost productivity. For instance, automated sealing machines expedite the packaging process by quickly sealing packages, eliminating the manual effort of taping or sealing. Semi-automated packing stations, featuring conveyors, label printers, and weighing scales, can significantly streamline the packaging process, reducing manual labor.

When considering packaging efficiency and automation, focus on these two key aspects:

1.Streamlining Packaging Processes:

Optimizing your packaging workflow is crucial to remove bottlenecks, cut down unnecessary steps, and enhance overall efficiency. This requires a thorough evaluation of your entire packaging process, from receiving orders to shipping, and pinpointing areas where resources might be wasted.

Key components to consider include:

- Order Processing: Inefficiencies in order processing can cause delays and errors. Issues often arise from a lack of automated systems in order fulfillment or poor coordination between departments. Implementing order management systems like Skuvault or Zoho Inventory can automate order verification, provide real-time updates, and manage inventory, thereby accelerating the process.

- Packaging Procedures: Establishing standardized packing procedures ensures consistency and reduces errors. Document specific packaging requirements, provide detailed instructions, and train personnel accordingly. This not only minimizes rework and errors but also makes it easier for team members to be cross-trained, leading to a more flexible and agile operation.

2.Warehouse and Inventory Management

Effective handling and organization of packaging materials are crucial in preventing delays and wastage. Disorganized storage can result in employees wasting time searching for the needed materials, causing frustrations and inefficiencies.

To enhance the storage and organization of packaging materials:

- Implement Proper Labelling Systems: This step is key in maximizing the efficiency of your storage spaces. Clear and systematic labelling allows for quick identification and retrieval of materials, saving both time and effort.

- Adopt Advanced Inventory Tracking Systems: Using technologies like barcode scanning or Radio Frequency Identification (RFID) can significantly improve the visibility of inventory levels and locations. This is particularly beneficial for businesses dealing with a diverse range of products. Efficient stock management reduces the likelihood of stockouts, which can otherwise cause delays in the packaging process.

By optimizing warehouse and inventory management, businesses can streamline their operations, reduce time wastage, and ensure a more efficient packaging process. This, in turn, leads to cost savings and a smoother workflow overall.

Cost-Effective Packaging Strategies for Businesses

In business, costs are inevitable, whether it's for marketing, customer service, or product packaging. To manage these expenses effectively, consider integrating the following cost-effective packaging strategies:

1.Utilize Efficient Design (FEFCO Styles)

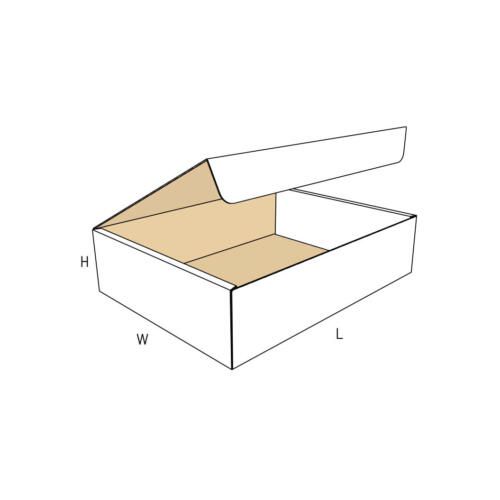

The Fédération Européenne des Fabricants de Carton Ondulé, representing corrugated fibreboard cardboard producers, offers a comprehensive catalog of designs. These designs not only standardize packaging but also maximize material efficiency, reducing waste. With about 200 FEFCO codes, suppliers can provide various options, like the classic corrugated mailer box (FEFCO 0427) and the standard slotted-type shipping box (FEFCO 0201). By choosing these efficient designs, businesses can save on material costs while maintaining packaging quality.

2.Right-sizing Packaging

Right-sizing packaging involves choosing the most suitable packaging size for each product, thereby minimizing the need for extra void fill and reducing wasted space. This approach is about ensuring the packaging is as close to the product dimensions as possible, eliminating the necessity for excessive cushioning materials and, consequently, lowering overall packaging material costs.

Moreover, right-sizing packaging can also lead to reduced shipping costs. This is because it helps avoid extra charges associated with dimensional weight, a pricing technique that considers package volume in addition to its actual weight.

3.Collaborative Partnerships and Supply Chain Optimization

Effective supply chain management through collaboration is key to efficiently addressing packaging needs. This involves coordinating not just within your organization but also with external partners.

Engaging in collaborative partnerships across your supply chain can lead to significant cost management benefits in the long term. By working closely with suppliers, manufacturers, and logistics providers, you can streamline processes, identify cost-saving opportunities, and optimize the entire supply chain for packaging.

These partnerships can provide insights into more efficient packaging methods, bulk purchasing advantages, and even shared logistics solutions. The goal is to create a symbiotic relationship where both your business and your partners benefit from reduced costs, improved efficiency, and enhanced operational effectiveness.

4.Consultation with a Packaging Expert

Seeking advice from a packaging expert can be a game-changer in reducing packaging costs. An expert in packaging design is well-versed in the strategies previously discussed and can offer invaluable insights specific to your business needs.

A seasoned package designer will assess your current packaging materials and practices, aiming to consolidate and streamline your packaging inventory. This approach not only ensures efficient use of materials but also capitalizes on economies of scale.

By consulting with a packaging expert, you can expect to see reductions in costs associated with machine setup, tools, and the procurement of packaging materials. Their expertise can guide you towards more cost-effective, sustainable, and practical packaging solutions, ultimately enhancing your overall packaging strategy.

DOBBPKING is a service provider specializing in paper-based environmentally friendly packaging. It has rich production experience and advanced equipment. Consulting packaging experts, we can provide you with customized, cost-effective packaging solutions.

Want to customize your tube or box packaging solution? Leave your needs below and our experts will contact you soon!